In the plastics industry, appearance is just as important as functionality. Whether it’s packaging, industrial containers, or textiles, consumers demand products that look appealing and perform consistently. Color masterbatch is the solution that allows manufacturers to achieve vibrant colors, strong durability, and reliable quality. By dispersing pigments and additives into a polymer carrier, color masterbatch ensures consistent coloration across a wide range of plastic applications.

1. What is Color Masterbatch?

Color masterbatch is a concentrated mixture of pigments and additives, encapsulated in a carrier resin. It is added to raw polymer during processing to impart specific shades and effects. Compared with dry pigments, color masterbatch offers superior dispersion, reduced dust contamination, and easier handling.

The choice of carrier resin—such as PE, PP, or PET—ensures compatibility with the end-use polymer, delivering excellent processability and performance.

2. Applications of Color Masterbatch

Color masterbatch is widely used in plastic packaging.

2.1. Blown Film (Plastic Bags)

Color masterbatch is widely used in films for T-shirt bags, shopping bags, garbage bags/ trash bags, and food packaging. It ensures opacity, UV resistance, and consistent colors that enhance brand identity.

2.2 Blow Molding (Cans and Bottles)

In blow molding, color masterbatch is critical for producing:

-

Household bottles where appearance directly influences consumer choice.

-

Industrial jerry cans for oils, lubricants, and chemicals that require opacity and chemical resistance.

By using color masterbatch, manufacturers achieve durability, fade resistance, and visual appeal even under harsh storage conditions.

2.3. Injection Molding (Containers and Household Goods)

Injection molding produces a wide range of consumer products:

-

Food containers that must meet safety standards.

-

Household items such as storage boxes, chairs, and kitchenware.

Color masterbatch improves surface finish, scratch resistance, and cost efficiency during high-volume production.

2.4. PP Woven & FIBC Bags

For woven packaging products, such as fertilizer bags, cement sacks, and jumbo FIBC bags, color masterbatch provides:

-

Uniform coloring across woven tapes.

-

UV stabilization for outdoor storage.

-

Long-lasting performance under heavy load.

This ensures bags not only look professional but also resist degradation in tough environments.

2.5. PP Non-Woven (Spunbond Fabrics)

In hygiene, agriculture, and medical applications, non-woven fabrics require color masterbatch to achieve:

-

Softness and whiteness for sanitary products.

-

Consistent shades for agriculture covers and medical textiles.

-

Breathability without affecting mechanical properties.

Here, the masterbatch contributes to both functionality and appearance.

2.6. Thermoforming

Thermoformed products like food trays, disposable cups… use color masterbatch to:

-

Enhance appearance for branding.

-

Ensure food-contact compliance.

-

Maintain clarity and gloss during forming.

2.7. Extrusion

In extrusion, color masterbatch is applied to:

-

Pipes and profiles that require weather resistance and uniform shades.

-

Plastic sheets used in construction and packaging.

Color masterbatch improves process stability, surface quality, and UV protection, ensuring long product lifespans.

2.8. Rotomolding/ blow molding

Rotomolding creates large, hollow products (water tank, trash bin, corn…). Color masterbatch ensures:

-

Even pigment dispersion throughout the product wall.

-

UV resistance for outdoor applications like water tanks and playground equipment.

-

Long-term durability against fading and weathering.

3. Advantages of Using Color Masterbatch

- Vibrant and Consistent Colors – Provides accurate shades and batch-to-batch uniformity.

- Improved Processability – Enhances mixing, reduces production defects, and ensures smooth extrusion or molding.

- Cost Efficiency – More economical than liquid or powder pigments, reducing waste and downtime.

- Compatibility – Works with a wide range of polymers including PE, PP, PET, PVC, and more.

- Special Effects – Enables metallic, pearlescent, and transparent finishes to meet unique design needs.

4. Choosing the right supplier of color masterbatch

Not all color masterbatches are created equal. The right supplier provides:

-

Color Matching Services – to meet exact customer requirements.

-

Consistency – batch-to-batch reliability to avoid quality variations.

-

Compliance – FDA, RoHS, and REACH certified formulations for global standards.

-

Technical Support – helping manufacturers optimize processing and reduce costs.

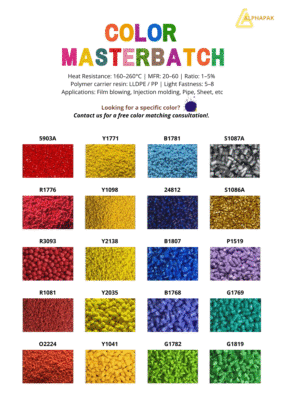

At Alphapak, we provide tailor-made color masterbatch solutions to meet diverse industry needs. Our products ensure vibrant colors, excellent dispersion, and superior performance across applications.

Color masterbatch is more than just a coloring agent—it is the backbone of plastic design and performance. From films and bottles to textiles, injection molding, and rotomolding, it ensures products are attractive, durable, and reliable.

If you’re looking for a trusted partner to supply high-quality color masterbatch, Alphapak is here to support your business with tailored solutions.

📩 Alice – Sales Manager

✉️ Email: alice@alphapak.vn

📱 WhatsApp: +84869572065