1. Introduction

Are you a plastic manufacturer facing rising raw material costs? You’re not alone. With the price of virgin plastic resins fluctuating and global demand increasing, manufacturers are under pressure to find smarter ways to reduce costs without sacrificing quality.

Filler masterbatch has become one of the most widely used solutions in the plastics industry. By partially replacing virgin resin with cost-effective mineral fillers such as calcium carbonate (CaCO₃), it helps manufacturers reduce production costs, improve processing, and even enhance certain mechanical properties.

In this guide, we’ll cover everything you need to know about filler masterbatch – from its composition and production to its advantages, applications, and market trends.

2. What Is Filler Masterbatch?

Filler masterbatch is a concentrated mixture of mineral fillers, polymer carriers, and additives used to reduce the cost of plastic production. It is usually added directly into plastic processing equipment (extruders, injection molding machines, blow molding lines) during production.

Key components:

-

Filler (CaCO₃, Talc, BaSO₄): Provides bulk, reduces resin usage, and modifies mechanical/optical properties.

-

Polymer Carrier (PE, PP, etc.): Ensures compatibility with the base resin.

-

Additives (optional): Improve dispersion, processing, or product performance (e.g., anti-moisture, anti-scratch).

In most cases, CaCO₃ filler masterbatch contains 60–85% calcium carbonate dispersed in PE or PP carrier.

Learn more about calcium carbonate applications in plastics (AZoM).

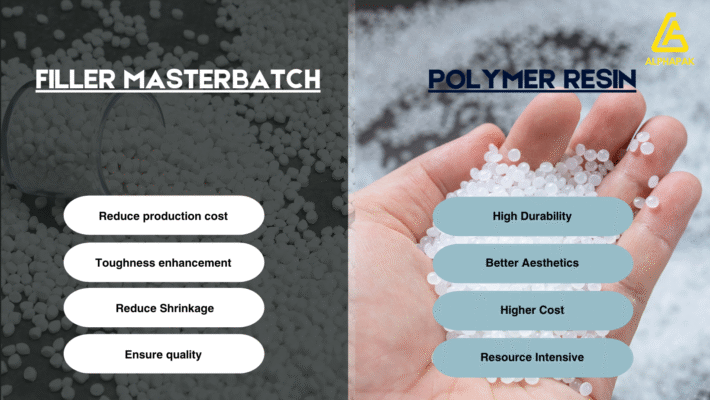

3. Resin vs. Filler Masterbatch

Virgin plastic resins are 100% polymer, which makes them expensive and heavily reliant on petroleum resources. Filler masterbatch provides a cost-saving alternative:

-

Virgin Resin: 100% polymer → expensive, high environmental footprint.

-

Filler Masterbatch: Polymer + filler → lower cost, reduced resin dependency, often improved processability.

This makes filler masterbatch a practical solution for industries aiming to balance performance + cost-efficiency.

4. How Is Filler Masterbatch Produced?

The production of filler masterbatch involves several carefully controlled steps:

-

Selection of Filler: Ultra fine CaCO₃ powder with particle size typically under 2 microns.

-

Surface Treatment: CaCO₃ is coated with stearic acid to improve bonding with polymer.

-

Compounding: Filler is blended with polymer carrier (PE or PP…) and additives in a twin-screw/ triple screw extruder.

-

Extrusion & Cooling: Melted compound is extruded into strands and cooled.

-

Pelletizing: Strands are cut into uniform pellets (masterbatch form).

5. Key Advantages of Filler Masterbatch

Using filler masterbatch brings multiple benefits beyond cost reduction:

-

Lower Production Costs: Normally replace up to 20- 50% of virgin resin in some applications.

-

Improved Processing: Better thermal conductivity leads to reduced cycle time, smoother extrusion.

-

Enhanced Mechanical Properties: Improved stiffness, printability, and dimensional stability.

-

Better Surface Properties: Increased opacity, smoother surface finish, reduced shrinkage.

-

Sustainability: Reduces reliance on petroleum-based polymers.

6. Applications of Filler Masterbatch

Filler masterbatch is highly versatile and widely applied in multiple plastic industries:

-

Blown Film: Shopping bags, garbage bags, T-shirt bags, agricultural films.

-

Extrusion: Pipes (PP, HDPE), sheets, thermoformed products.

-

Injection Molding: Household items, automotive parts, industrial containers.

-

Non-Woven Fabrics: Packaging, hygiene products.

-

Blow Molding: Bottles, containers, and drums.

-

Woven Sacks & Raffia: Cement bags, PP woven sacks, FIBC jumbo bags.

7. Market Trends in Filler Masterbatch

The filler masterbatch market is experiencing rapid growth, especially in Asia, Africa, and Latin America where cost competitiveness is critical. Key trends include:

-

High Demand in Emerging Markets: Cost-saving solutions for flexible packaging and household plastics.

-

Shift Toward Sustainability: Combining filler masterbatch with biodegradable or recycled plastics.

-

Innovation in Additives: Anti-moisture (desiccant) filler masterbatch for recycling, high-dispersion grades for thin films…

8. Why Choose Alphapak as Your Filler Masterbatch Partner?

At Alphapak, we provide tailor-made filler masterbatch solutions designed to help you reduce costs while maintaining quality. Our products are optimized for PE, PP, and multi-layer applications, with:

-

High CaCO₃ loading (up to 85%).

-

Excellent dispersion & compatibility with base resins.

-

Custom formulations for film, injection, extrusion, or woven sack applications.

-

Consistent quality & competitive pricing and great logistic service for global markets.

9. Conclusion

Filler masterbatch is no longer just an optional additive – it’s a core material for modern plastic manufacturing. By reducing resin costs, improving performance, and supporting sustainability goals, it has become essential for plastic processors worldwide.

If you’re looking to boost your profitability and efficiency, Alphapak’s filler masterbatch solutions are here to support your success.

Let’s contact us today for your suitable filler masterbatch and free sample:

✉️ alice@alphapak.vn | 📱 WhatsApp/ Viber/ Mobile Phone: +84 869 572 065