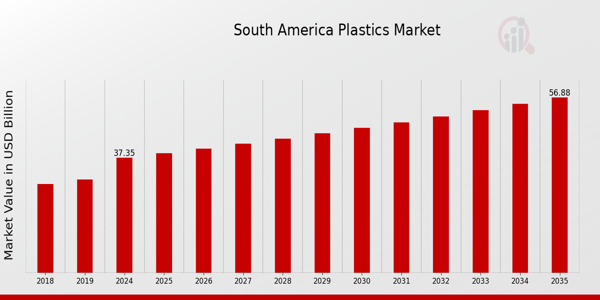

The plastics industry in South America is expanding rapidly, fueled by rising demand for packaging, infrastructure, automotive, and consumer goods. Manufacturers are seeking innovative raw material solutions that combine quality, cost-efficiency, and sustainability. At the core of this transformation is the role of masterbatch—a concentrated mix of pigments or additives used to enhance plastics.

As a trusted masterbatch supplier in South America, Alphapak partners with trading companies, distributors and manufacturers to deliver consistent performance across industries.

1. Why Choose a Reliable Masterbatch Supplier in South America?

Working with a reliable supplier is crucial. It ensures:

-

Stable quality – avoiding color inconsistency or processing issues.

-

Cost savings – by reducing raw material waste and improving processability.

-

Application-specific performance – from UV resistance for agriculture films to food-contact safety for packaging.

-

Sustainable options – helping producers meet global and regional environmental standards.

Alphapak combines global know-how with customer-centric solutions, ensuring that South American clients have access to the latest masterbatch innovations.

2. Applications of Masterbatch in South America

2.1. Packaging and Blown Film

South America’s food and beverage sector demands high-quality flexible packaging. Color and additive masterbatch are widely used in plastic bags, shrink films, and multilayer food packaging to achieve barrier protection, clarity, and shelf appeal.

With agriculture being a cornerstone of South America’s economy, UV masterbatch and stabilizers are critical for greenhouse films, mulching films, and irrigation pipes. These solutions extend product life under intense sunlight, especially in regions like Brazil’s Cerrado.

2.2. Blow Molding (Cans and Bottles)

From household cleaning products to edible oil bottles, blow molding masterbatch ensures durability, gloss, and regulatory compliance. This application is especially strong in Brazil and Colombia, where demand for PET and HDPE bottles continues to grow.

2.3. Injection Molding (Household and Industrial Goods)

Masterbatch supports the production of containers, crates, chairs, and technical parts, ensuring color uniformity and mechanical strength. Manufacturers in Argentina and Chile rely on injection molding for consumer goods distribution.

2.4. Infrastructure and Construction

Pipes, cables, and sheets produced with black and additive masterbatch provide long-lasting performance and resistance to harsh weather. Demand is increasing in fast-growing urban areas like São Paulo, Buenos Aires, and Lima.

2.5. Textiles: PP Woven and Non-Woven

South America is a strong producer of woven sacks, jumbo bags (FIBC), and spunbond nonwoven fabrics. Here, masterbatch ensures consistency in color and strength, supporting industries such as agriculture, fertilizer, and hygiene products.

3. Why Alphapak is the Right Partner

Alphapak is proud to be one of the prestigious masterbatch supplier in South America. We provide:

-

Wide product portfolio: color masterbatch, black/white masterbatch, additive solutions (anti UV, desiccant, etc.), and CaCO₃ filler masterbatch.

-

Customized solutions tailored to local customer needs. We have Color Matching and Formula Creation Services to meet exact customer requirements.

-

Technical support and training for processing optimization.

-

Competitive logistics advantage with reliable shipping to South American ports.

South America is not only a growing market but also one that values sustainability. Alphapak provides:

-

Eco-friendly solutions with biodegradable carrier resins.

-

Cost-saving and stiffness improvement with CaCO₃ filler masterbatch — CaCO₃ helps reduce virgin resin consumption, lowering material costs and enhancing product stiffness. Note: CaCO₃ is denser than polymers, so without design optimization, product weight may increase. That’s why manufacturers often adjust thickness, replacement ratio, and formulation to balance cost, performance, and weight.

Technical Note:

Polypropylene (PP) and polyethylene (PE) have a density of around 0.90–0.95 g/cm³, while calcium carbonate (CaCO₃) has a density of about 2.70 g/cm³. This difference means that using CaCO₃ filler masterbatch can increase product density. To offset this, converters often optimize product design (e.g., reducing thickness) to achieve cost savings without excessive weight gain. -

Energy savings via improved processability.

By choosing Alphapak as your masterbatch supplier in South America, you gain a partner committed to both performance and environmental responsibility.

To conclude, the plastics industry in South America is entering an era of innovation and sustainability. Partnering with the right masterbatch supplier ensures that your products meet the highest standards of quality, performance, and cost-effectiveness.

📌 Looking for a trusted masterbatch supplier in South America? Connect with Alphapak today.

Contact:

📧 Email: alice@alphapak.vn

📞 WhatsApp: +84 869 572 065