Masterbatch for Plastic Furniture plays a vital role in enhancing the color, durability, and performance of plastic products. According to the Plastics Industry Association, selecting the right masterbatch formulation is essential for achieving long-lasting performance and aesthetic consistency. At Alphapak, we provide high-quality masterbatch solutions specifically tailored for plastic furniture applications, ensuring vibrant colors, improved UV resistance, and long-lasting quality.

1. What is Masterbatch for Plastic Furniture?

Masterbatch is essentially a concentrated mixture of pigments and/or additives dispersed in a carrier resin, designed to blend easily with raw polymers during processing. The right masterbatch selection can:

-

Increase product lifespan with improved weather and UV resistance.

-

Enhance aesthetics with rich, uniform colors and unique surface effects.

-

Improve processability during injection molding or extrusion.

-

Lower production costs by reducing material waste and defects.

In plastic furniture manufacturing, three main types of masterbatch are commonly used:

-

CaCO₃ Filler Masterbatch – Primarily based on PP resin (with LLDPE and HDPE also used), this type reduces production costs, improves stiffness, and enhances surface finish.

CaCO3 filler masterbatch for plastic furniture -

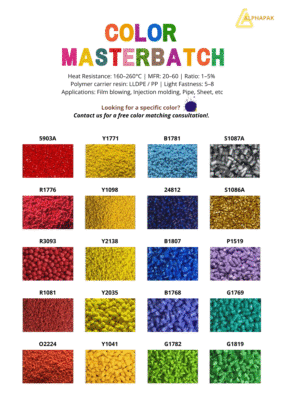

Color Masterbatch – Provides vibrant, uniform, and long-lasting colors to match brand requirements.

Popular grades of color masterbatch from Alphapak Vietnam -

Functional Additive Masterbatch – Includes UV stabilizers, antioxidants, and other performance enhancers to protect against environmental stress, such as sunlight, moisture, and impact.

There are some key Benefits for Plastic Furniture:

-

Excellent Color Consistency – Whether it’s a sleek white dining chair or a bold red patio set, Alphapak’s color masterbatch ensures every production batch maintains the exact tone and vibrancy.

-

UV Resistance for Outdoor Use – Our UV additive masterbatch protects against fading, brittleness, and degradation, keeping outdoor furniture attractive and durable for years.

-

High Mechanical Strength – Enhanced impact resistance and structural stability allow furniture to handle heavy loads without compromising style.

-

Versatile Design Options – Achieve glossy, matte, metallic, or marble-like effects to create standout products in a competitive market.

2. Applications of Masterbatch in Plastic Furniture

-

Chairs & Tables – For both indoor dining and outdoor leisure.

-

Storage Units – Plastic cabinets and drawers with enhanced rigidity.

-

Garden Benches & Loungers – UV-protected, weather-resistant designs.

-

School Furniture – Bright, safe, and durable seating for classrooms.

-

Office Furniture – Professional, sleek finishes for workspaces.

3. Tips for Choosing the Right Masterbatch for Plastic Furniture

-

Consider End Use – Indoor vs. outdoor use will determine the level of UV stabilizers required.

-

Match Processing Method – Injection molding and extrusion may require different masterbatch properties.

-

Select Compatible Carrier Resins (PP, LDPE, LLDPE, HDPE) – To ensure proper dispersion and performance.

-

Evaluate Long-Term Costs – A high-quality masterbatch may cost slightly more but can significantly reduce defects and returns.

4. Why Partner with Alphapak?

At Alphapak, we don’t believe in one-size-fits-all solutions. Our R&D team works closely with furniture manufacturers to develop masterbatch formulations tailored to specific needs.

-

Custom Formulations – Tailored to your production parameters and material needs.

-

Technical Support – Our experts assist throughout the process, from sample design, sample running to manufacturing process.

-

Consistent Quality – We adhere to strict quality control standards.

-

Competitive Pricing – High performance at cost-effective rates.

The success of plastic furniture manufacturing depends heavily on the quality of the materials used – and masterbatch plays a critical role in defining that quality. By choosing Alphapak’s masterbatch for plastic furniture, manufacturers can produce products that are not only visually appealing but also durable, sustainable, and market-ready.

If you’re looking to enhance your plastic furniture production with advanced masterbatch solutions, Alphapak is your trusted partner.

📞 Contact Alphapak today to learn more about our custom formulations and how we can help your furniture products stand out.

- Email: alice@alphapak.vn

- Mobile/ WhatsApp/ Viber: (+84) 869 572 065 (Ms Alice- Sales Manager)