Polypropylene (PP) woven fabrics have become indispensable across industries like packaging, agriculture, construction, and transportation. From cement bags to rice sacks and geotextiles, PP woven materials offer strength, durability, and cost-efficiency. Behind their reliable performance lies a key ingredient: masterbatch for PP woven.

In this article, we explore what masterbatch is, why it’s critical in the production of PP woven fabrics, and how choosing the right formulation can lead to better performance, easier processing, and lower costs.

1. What is Masterbatch for PP woven?

A masterbatch is a concentrated mixture of additives, pigments, or fillers encapsulated into a carrier resin, typically the same as the base polymer—in this case, polypropylene (PP).

According to Plastics Europe, polypropylene is one of the most widely used thermoplastics globally, with versatile applications including woven sacks and packaging.

Masterbatch is added during the extrusion or molding process to modify specific properties of the plastic without altering the base resin’s mechanical characteristics.

In PP woven fabric manufacturing, masterbatch serves several essential functions:

-

Enhancing color and aesthetics

-

Improving processing stability

-

Lowering raw material costs (especially with filler masterbatch)

-

Protecting against UV degradation or improving other performance factors

2. Types of Masterbatch for PP Woven Fabrics

There are two main types of masterbatch for PP woven that manufacturers typically use:

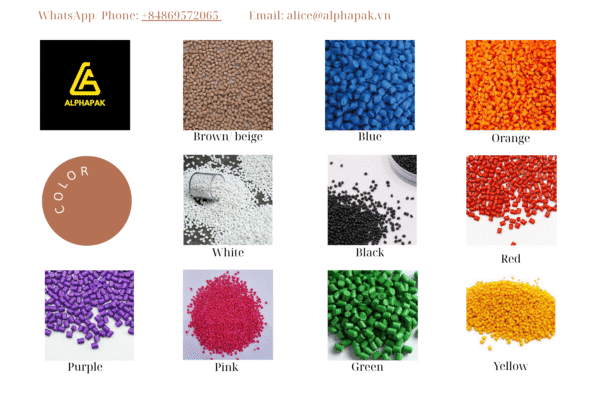

2.1. Color Masterbatch

Color masterbatch is used to give PP woven products consistent, vibrant, and long-lasting colors. It must have excellent dispersion properties to ensure even coloring and no visible streaks or patchiness in the final product.

For applications like fertilizer bags, shopping bags, or branded packaging, high-quality color masterbatch is essential to meet visual and branding expectations.

2.2. Filler Masterbatch

Filler masterbatch contains high-load calcium carbonate (CaCO₃) or talc and is widely used to reduce the cost of production. It replaces a portion of virgin PP resin while improving stiffness, printability, and dimensional stability. In PP woven production, it also contributes to smoother film surfaces, easier lamination, and higher output rates.

The right filler masterbatch:

-

Offers ultra-fine dispersion

-

Minimizes wear on machinery (screw, die, etc.)

-

Reduces yarn breakage during weaving

-

Improves output consistency

CaCO3 filler masterbatch for jumbo sack and PP woven bag

3. Benefits of Using Masterbatch in PP Woven Production

Using specialized masterbatch for PP woven offers multiple advantages:

- Cost Reduction

Filler masterbatch allows manufacturers to partially replace expensive virgin PP with cost-effective fillers without compromising fabric strength or appearance. This results in significant savings—especially for high-volume producers.

- Improved Yarn Quality

Masterbatches with proper dispersion agents and particle sizing help maintain yarn consistency, reduce denier variation, and minimize filament breakage during weaving.

- Enhanced Surface Finish

Color and filler masterbatches contribute to smooth film surfaces, enabling better lamination and print adhesion for BOPP films or multi-layer packaging.

- Better Machine Performance

A good masterbatch improves flowability, prevents die buildup, and reduces downtime caused by blockages or wear, leading to more stable operations and higher output.

- Customization for End Use

Masterbatch can be tailored with additives like UV stabilizers, anti-blocking agents, or anti-slip components to meet specific requirements—whether for outdoor exposure, food-grade applications, or anti-static properties.

4. Choosing the Right Masterbatch Supplier

Not all masterbatches are created equal. Poor-quality masterbatch can lead to machine clogging, yarn breakage, color inconsistencies, and reduced fabric strength. When selecting a masterbatch for PP woven, it’s essential to consider:

-

CaCO₃ purity and particle size

-

Compatibility with your PP resin grade

-

Dispersion quality and additive composition

-

Technical support and consistency across batches

Working with a reliable supplier like Alphapak ensures that the masterbatch is specially engineered for PP woven applications, delivering both performance and cost-effectiveness.

The role of masterbatch for PP woven is far more than just a colorant or filler—it’s a critical component that influences every aspect of the product: strength, appearance, cost, and processability. Whether you’re producing agricultural tarps, cement sacks, or shopping bags, investing in high-quality masterbatch can optimize your production process, lower waste, and enhance product value.

To stay competitive in the PP woven industry, choosing the right masterbatch partner is just as important as selecting the right machinery or fabric design.

Contact us now for free consultation and free sample:

- Email: alice@alphapak.vn

- Mobile/ WhatsApp: (+84) 869 572 065 (Ms Alice- Sales Manager)